More Than Meets the Eye: How a Catalyst's Shape Powers the Process

Discover why industrial catalysts come in powders, pellets, extrudates, and monoliths. This guide explains how physical form dictates reactor design, efficiency, and durability.

Shandong Dengzhuo Chemical Co., Ltd.

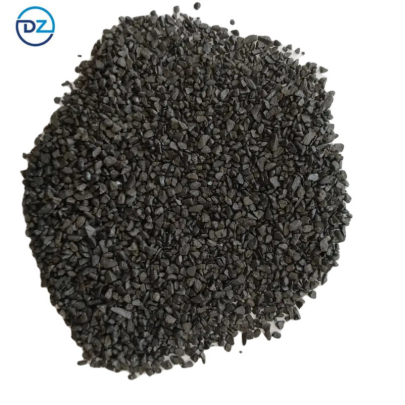

Dengzhuo Chemical has been pioneering manufacture synthesis gas catalysts for petrochemical, refinery and steel complexes in China, and we are an integrated enterprise which includes research,development and production. Our products include methanol synthesis catalyst, steam-reforming catalyst for gaseous hydrocarbon,ammonia synthesis catalysts,methanation catalyst,FCC catalyst, sulfuric acid catalyst and oil refining catalyst.

Our factory have more than 6000M2, and there are 30 scientists and technical personnel involved in the R&D and production of various types of catalysts. Therefore we will provide with our professional service to our customers form all over world.

Cost-effective

Technical Team

Fast Delivery

What we do

What we do

Our Advantage

Our Advantage

With modern production capacity and strict quality control, our production materials, processes, and technical quality continue to improve.

Our latest news.

Our latest news.

Discover why industrial catalysts come in powders, pellets, extrudates, and monoliths. This guide explains how physical form dictates reactor design, efficiency, and durability.

Discover how zeolite catalysts work. This article explains their unique porous structure, acid catalysis, and vital role in oil refining, chemicals, and environmental protection in an accessible way.

This article explores the vital role of steam reforming catalysts—especially nickel-based systems—in producing hydrogen from methane and other hydrocarbons. Learn how these catalysts work, why they’re so widely used, and what makes them essential for both today’s industry and a cleaner energy future.

Explore the versatile world of nickel-based catalysts supported on alumina. This guide breaks down the different types, their key characteristics, and common industrial applications—helping you understand how these catalysts drive efficiency in processes like hydrogenation, reforming, and syngas production.

Explore the essential partnership between catalysts and molecular sieves in industrial chemistry. Learn how common catalysts like Cu-Zn-Al and Ni-based systems work with molecular sieves like ZSM-5, SAPO-34, and MCM-41 to drive efficient and selective chemical reactions. A must-read for procurement and engineering professionals.

Explore the differences between MTO and MTP catalysts in methanol-based olefin production. This guide breaks down how each catalyst works, their unique advantages, and key factors to consider when selecting the right technology for your plant.

Explore the critical role of Hydrodesulfurization (HDS) catalysts in producing clean fuels. Learn how Co-Mo & Ni-Mo catalysts work to remove sulfur, meet stringent environmental regulations, and improve refinery efficiency and profitability.

Explore Copper-Zinc-Aluminum catalysts: vital for methanol synthesis, hydrogen production & gas shift reactions. Learn applications, benefits, handling needs, and sourcing importance.

Specialized catalysts and adsorbents drive industrial efficiency in syngas conversion (ammonia/hydrogen), refining, steel purification, and molecular separations. Essential materials like molecular sieves and activated alumina optimize performance and purity.

Comparing Nickel and Ruthenium Catalysts for CO₂ Methanation: Key insights on their use in hydrogenation to produce sustainable methane.